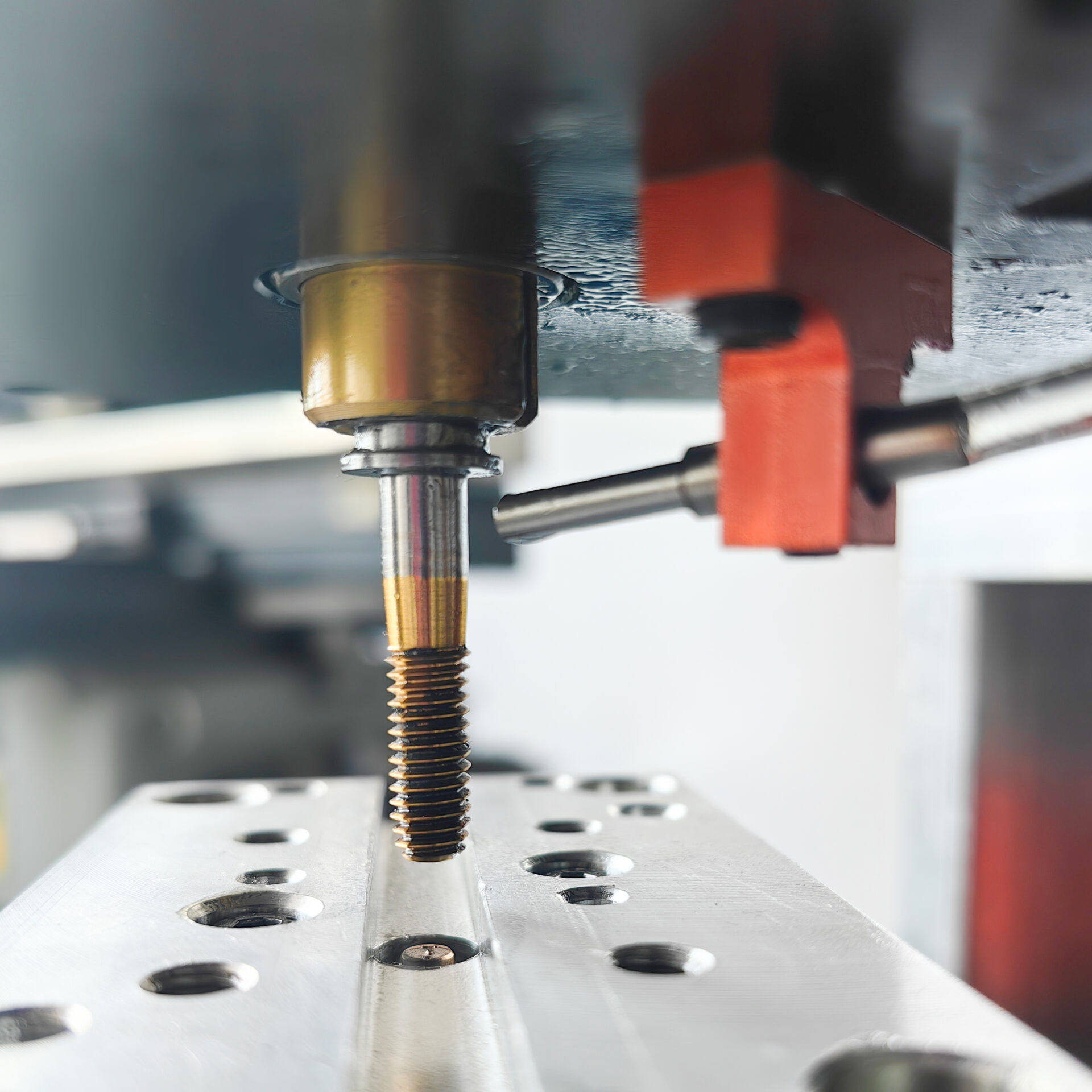

In-mold Tapping Solutions Supplier

BOMETT Assists In Automated Metal Stamping

As a professional In-mold Tapping Manufacturer,

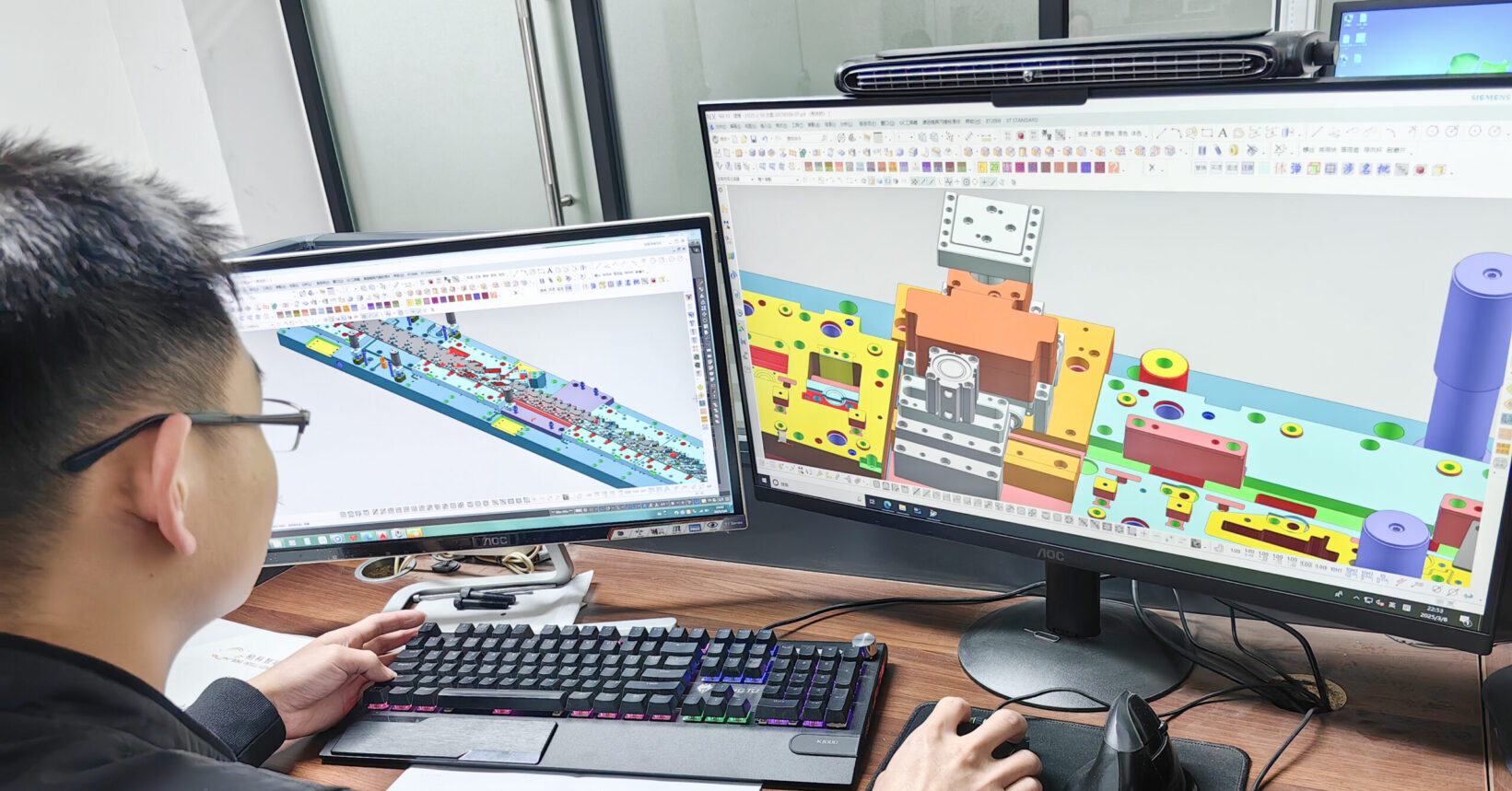

We Provide Custom Solutions & Versatile Tapping Units for Various Stamping Needs

柏迈特 BOMETT

BOMETT is Boke registered trademark.

We are deeply engaged in the tapping field of the metal stamping industry.

We are committed to providing customers with efficient and reliable tapping equipment and technical supports.

we have accumulated extensive project experience and can quickly provide customized solutions for the various complex tapping requirements.

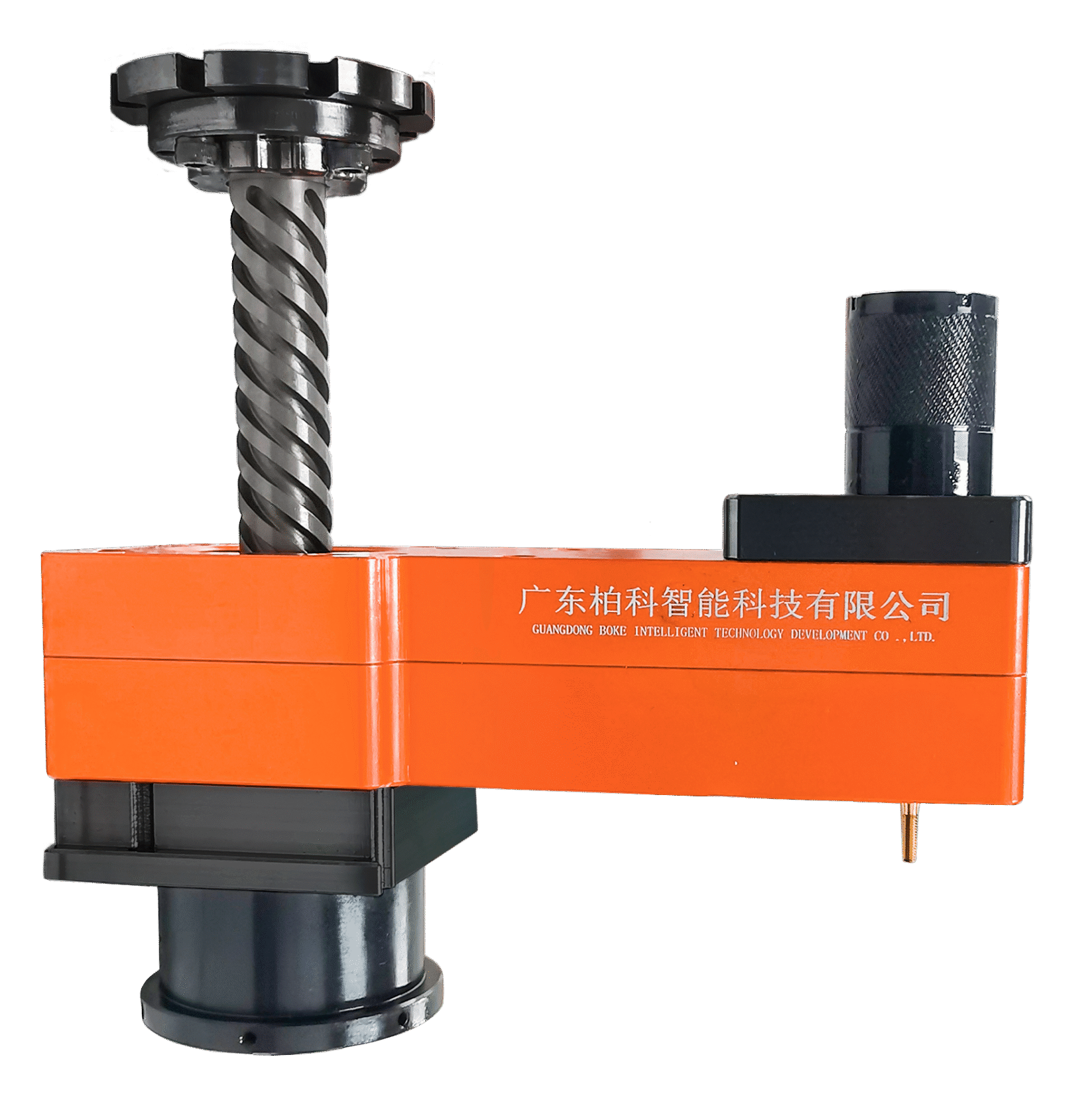

Professional manufacturer for in-mold tapping

Our Services

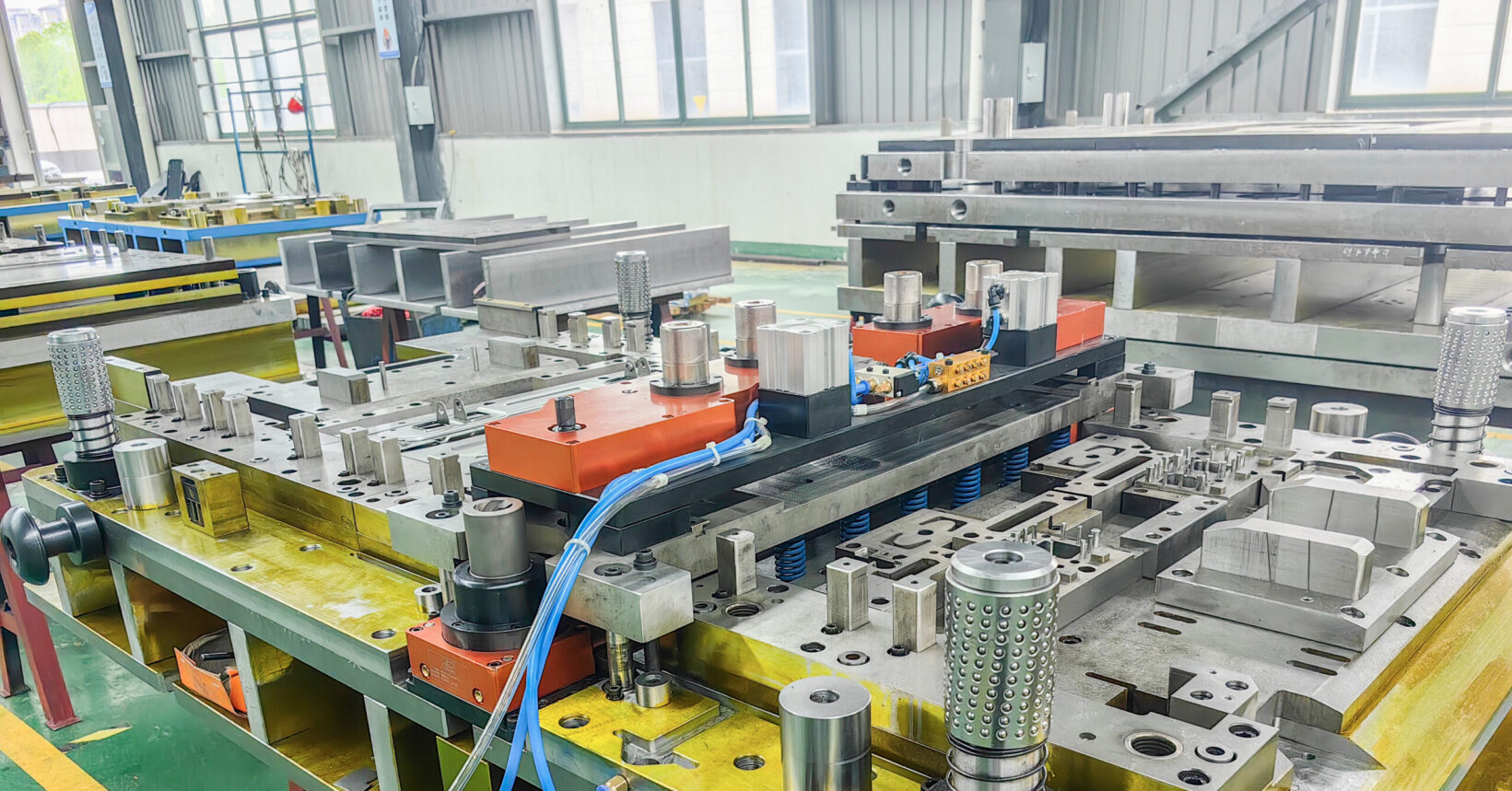

We provide professional in-mold tapping solutions and supporting equipment

Bomett will Flexibly match the optimal equipment solution according to customer production requirements and process requirements.

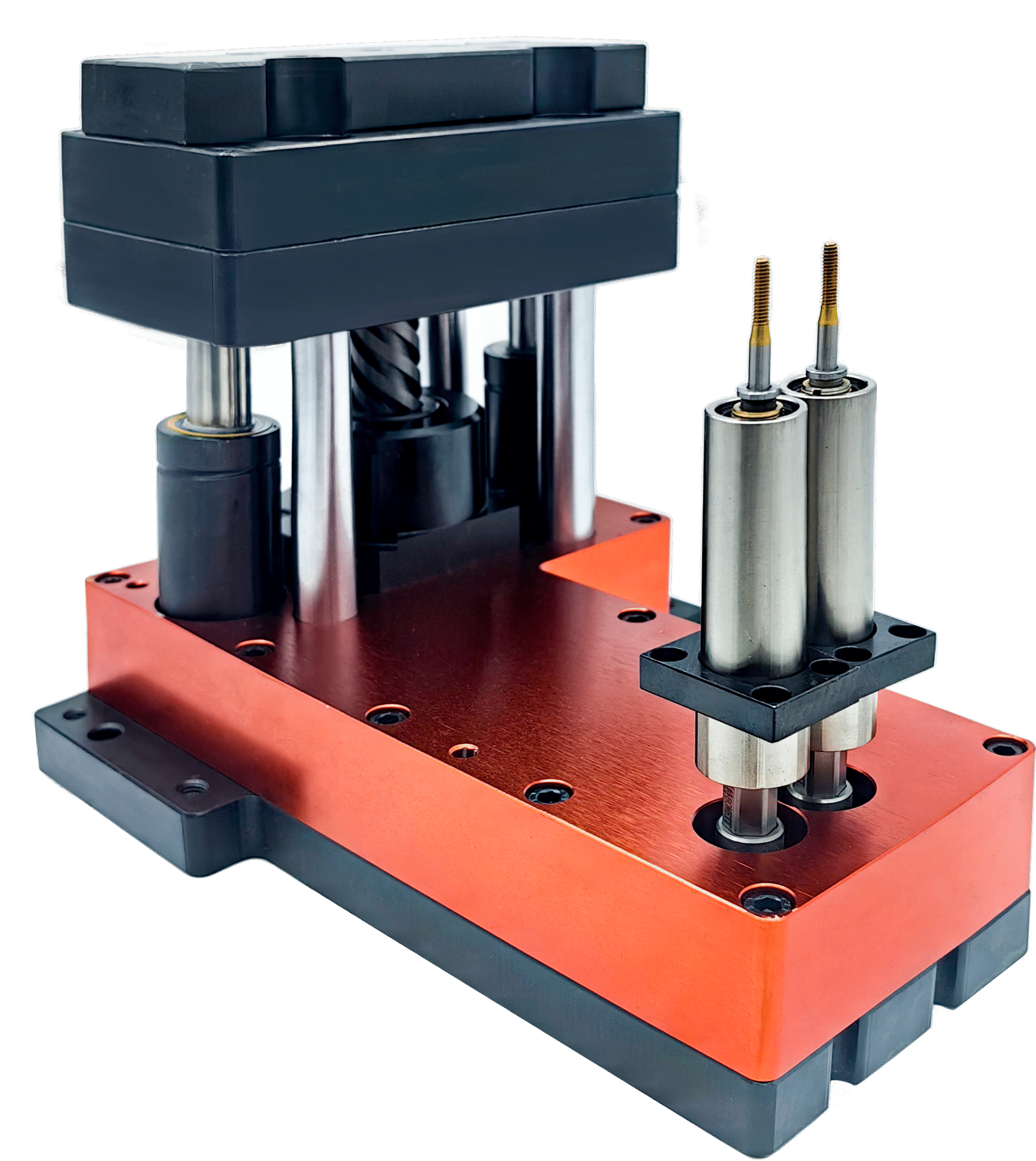

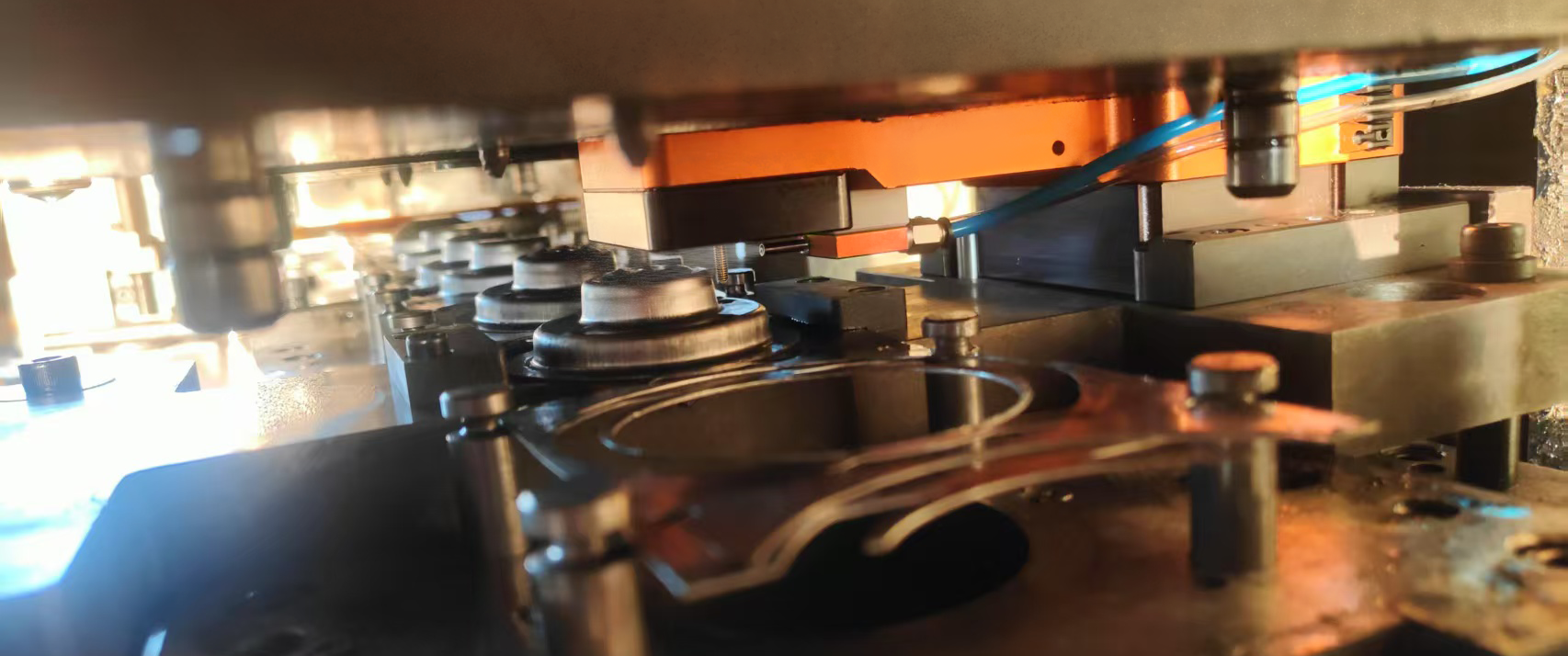

Our products cover a wide range of application scenarios, including mechanical in-mold tapping units with high stability suitable for traditional stamping needs, as well as a series of servo tapping machines for intelligent production.

We have also developed complementary tapping inspection equipment and tapping cooling devices.

Our Products

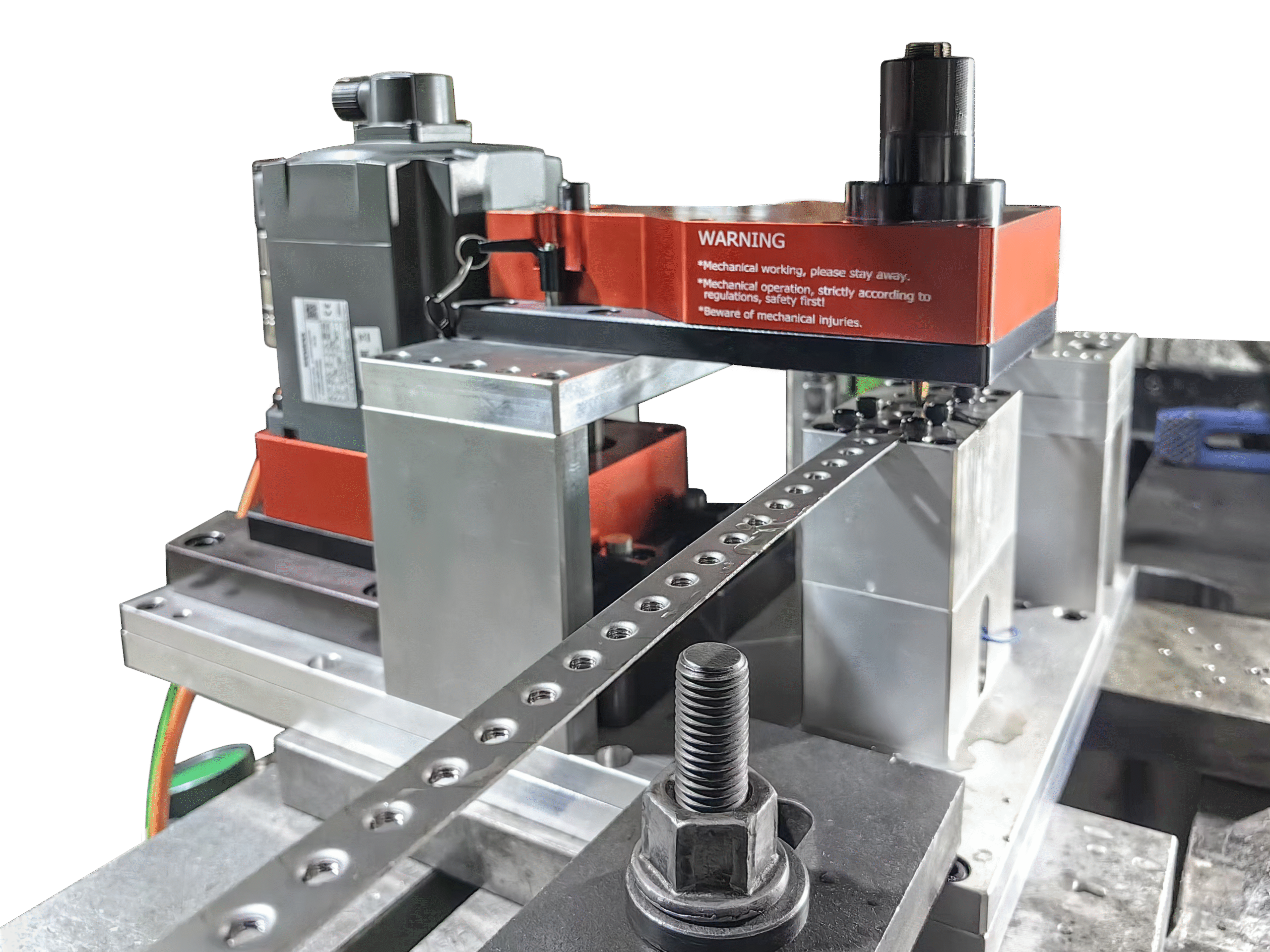

Application Cases

In-mold tapping technology has been widely used in the production of automotive parts, electronic appliances, hardware parts, motorcycle parts and other industries.

Why Use BOMETT

Using BOMETT in-mold processing system, we will handle all tapping and related problems

We not only handle in-mold tapping issues, but also have targeted solutions for related problems, addressing all your tapping concerns

Cut Cost

Our devices feature long service life, user-friendly operation, and easy maintenance—all designed to reduce your production costs.

Improve Efficiency

In-mold tapping or in-mold riveting is performed at the same time as stamping. The product is formed in one step without the need for secondary processing.

Higher Productivity

Automated production requires no manual operation or secondary processing. The tapping speed in the mold can reach up to 150 S.P.M.

Mature In-mold Processing System

For the problems derived from in-mold tapping, such as untapped tapping and inadequate feeding, we have targeted solutions.

Stable Quality

BOMETT devices ensure that the product will not miss tapping during the production process, ensuring consistent thread quality for each batch, reducing defects and improving efficiency.

Widely Applications

Has been widely used in electronic appliances, computer cases, auto parts, daily hardware, household appliances and other industries.

We Can Guarantee

We can provide professional pre-sales and after-sales services so that you can cooperate with us with confidence!

High & Stable Products

For any non-consumable component issues within 1 year, we provide free repair services to ensure your production continuity. With our high-quality devices, BOMETT is dedicated to empowering your automated production efficiency.

Competitive Price

BOMETT’s mature production system enables us to achieve cost optimization. This allows us to deliver high-quality, stable equipment while ensuring competitive pricing for all our customers.

Professional Services

All our employees possess extensive expertise. We are committed to delivering professional suggestions and tailored solutions to meet your specific needs. For any inquiries, our team guarantees a response within 24 hours.