BOMETT Tapping Unit

Technical Features of BOMETT Tapping Unit

Different brands have different design concepts.

This article will take the Bomett single-hole tapping models as an example to analyze our technical features and what kind of convenience it can bring to you.

Main Technical Features (Take BMT-R model as an example)

Using the following two single-hole models as the basis for the main explanation.

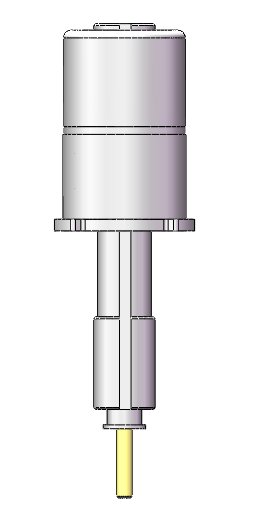

Structural Analysis 01 - Quick-release tap chuck & Built-in tap chuck

Quick-release tap chuck

Technical Features

- 1-Structure: have handles, tap shafts.

- 2-To replace the taps, you only need to remove the quick-release chuck to replace the tap without disassembling the tapping unit

- 3-Using quick-release tap chucks, need to ensure that the punch stroke is greater than 100mm.

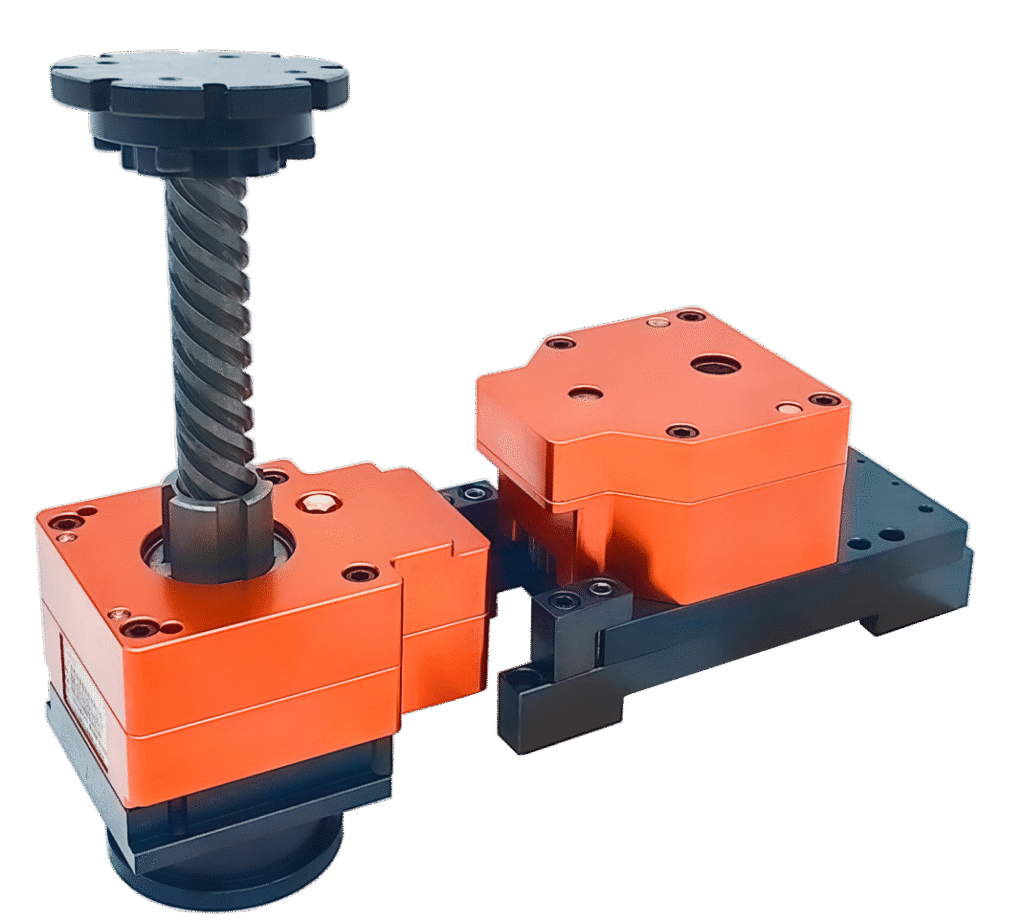

Actual tapping unit comparison (The main body of the tapping unit)

Structural Analysis 02 - Integral Structure & Separated Structure

Integral structure

The same integral structure, the comparison between quick-release tap chuck and built-in tap chuck

Technical Features

- 1-The integral structure has only one main tapping unit body

- 2-Both quick-release tap chucks and built-in tap chucks are adaptable. The specific design depends on the punch stroke.

- 3-This article takes a single-hole model as an example. For multi-hole integral models, the structure is similar and the appearance may change according to the product characteristics.

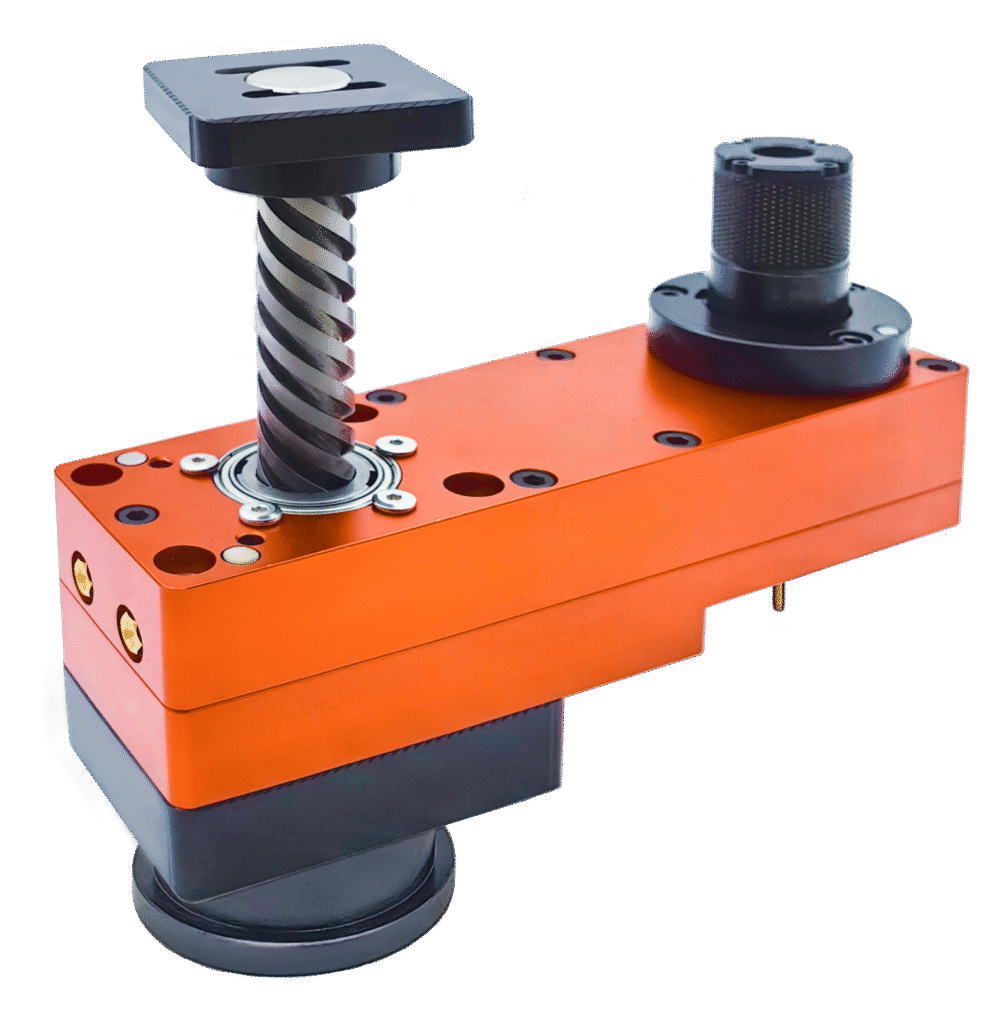

▼ Integral structure + quick-release tap chuck

▼ Integral structure + built-in tap chuck

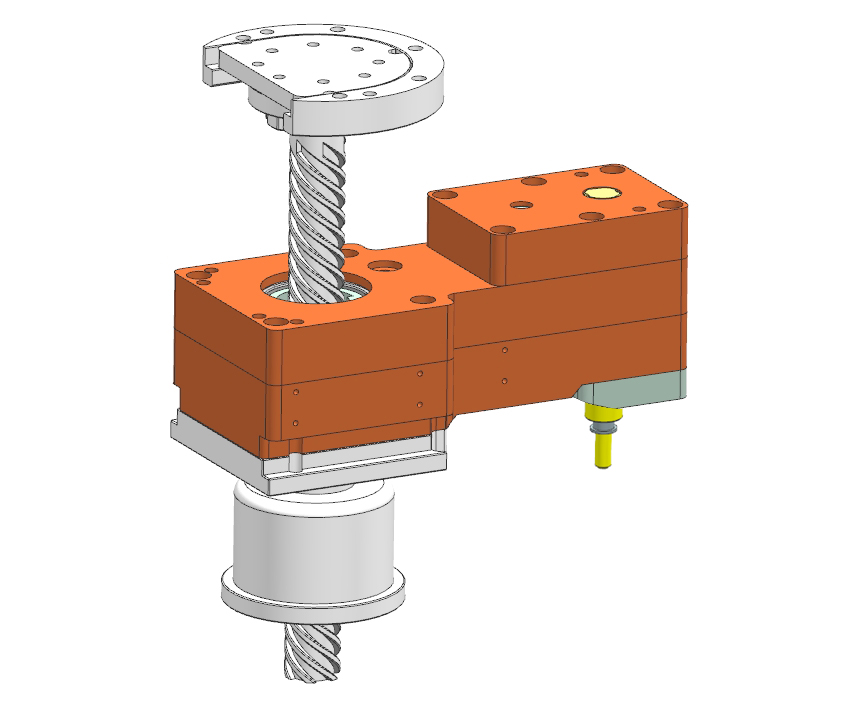

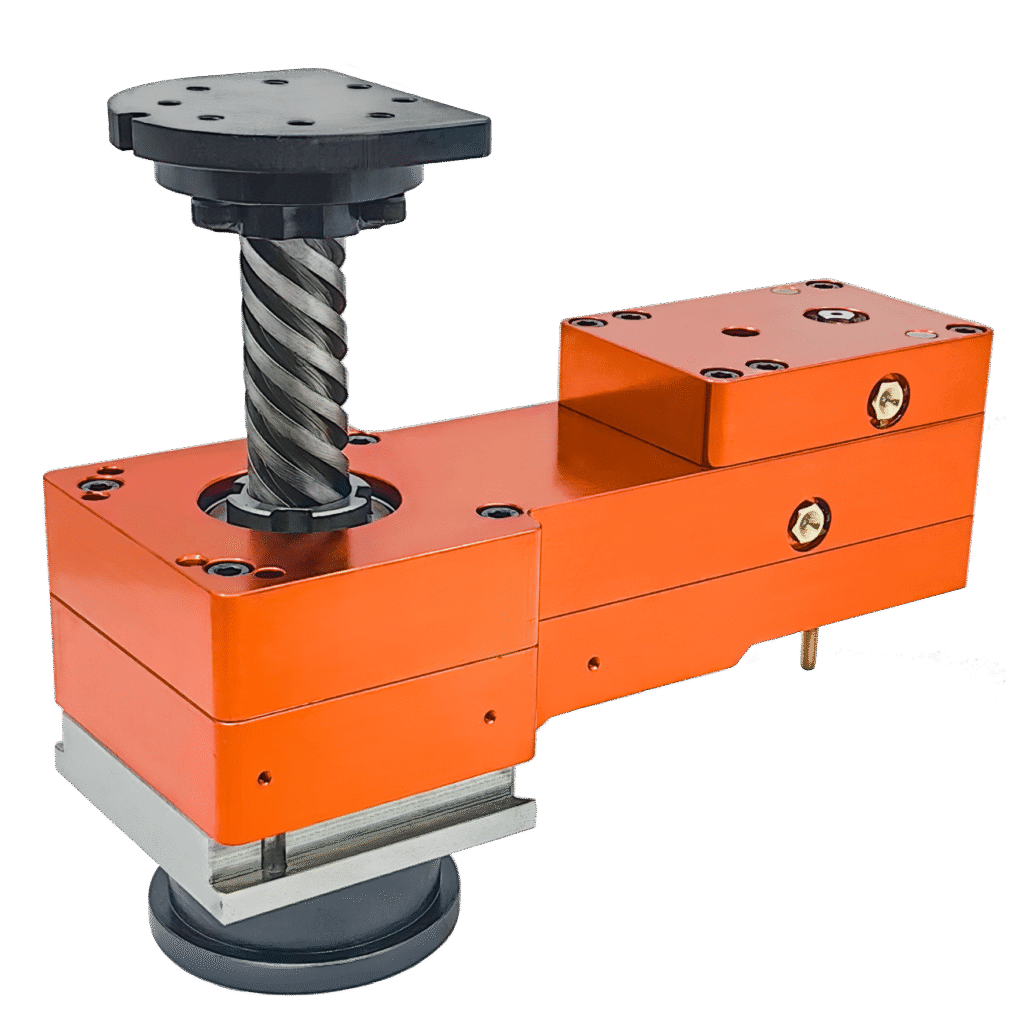

Separated structure

The composition of the separated structure

Technical Features

- 1-The main tapping unit body of the separated structure is composed of the tapping end and the driving end.

- 2-Both quick-release tap chucks and built-in tap chucks are adaptable. The specific design depends on the punch stroke.

- 3-This structure is more convenient for disassembling and replacing taps in small stroke design.

- 4-This article takes a single-hole model as an example. For multi-hole integral models, the structure is similar and the appearance may change according to the product characteristics.

LinkedIn

Facebook