Tap Detection

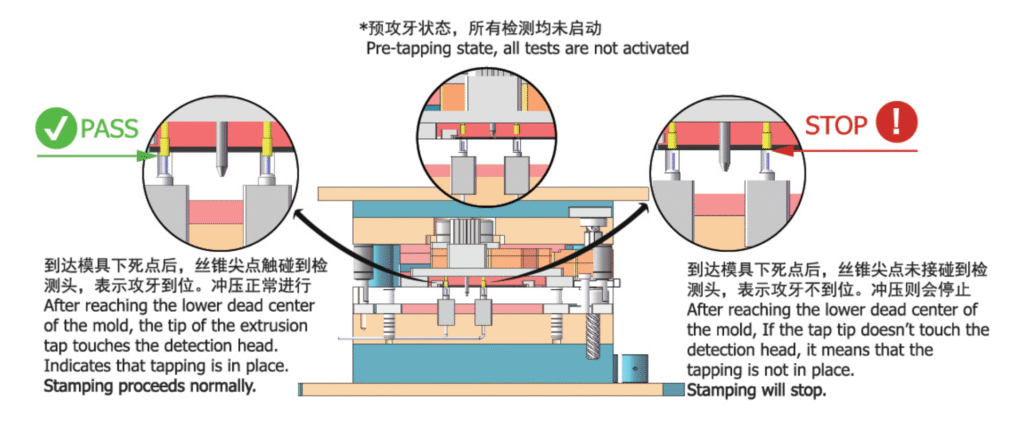

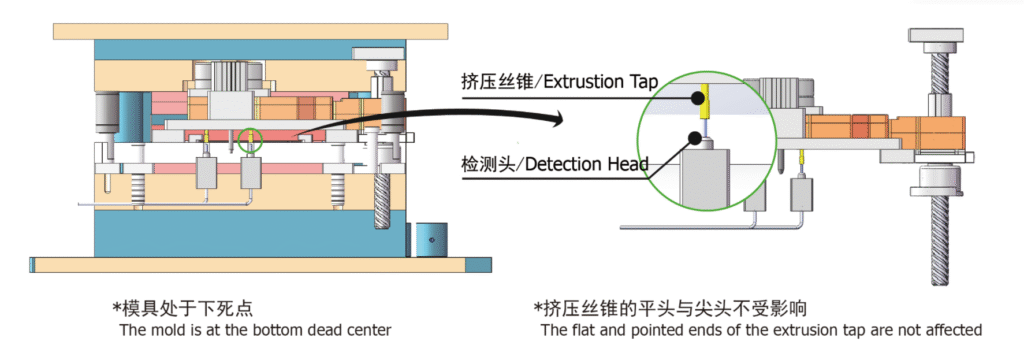

The purpose of the detection device is to detect problems such as incomplete tapping and tapping position deviation, effectively ensuring product qualification while also protecting the mold and tapping unit.

Tap detection, is mainly used to detect incomplete tapping.

If you want to know more about the detection device information, please contact the Bomett team.

We will provide professional advice in a timely manner.

Tap Detection

Technical Features

- A tapping head needs to be matched with a detection head.

- Detect broken taps,missing taps, tap installation errors and taps not in place.

- Designed for stamping processing,it replaces manual monitoring and performs real-time detection.

- Compact design, minimum center distance can be designed 18MM.

Testing Demonstration