Applications

Applicable industries: electronic appliances, computer cases, auto parts, daily hardware, household appliances and other industries.

Hardware Part

Demands

- 16 – M6*1.0, thread depth 4mm, material: cold rolled plate.

- Press stroke: 200mm.

- Production requirement: ≥30 S.P.M

Recommended Machine

- Based on the above customer needs, we adopted the combined design of the BK-ZON quick release tapping unit, equipped with 4 drive ends, to achieve high-speed mass production and stable tapping quality!

- Production videos can be found at: How to design a mold for tapping 16 threads one time?

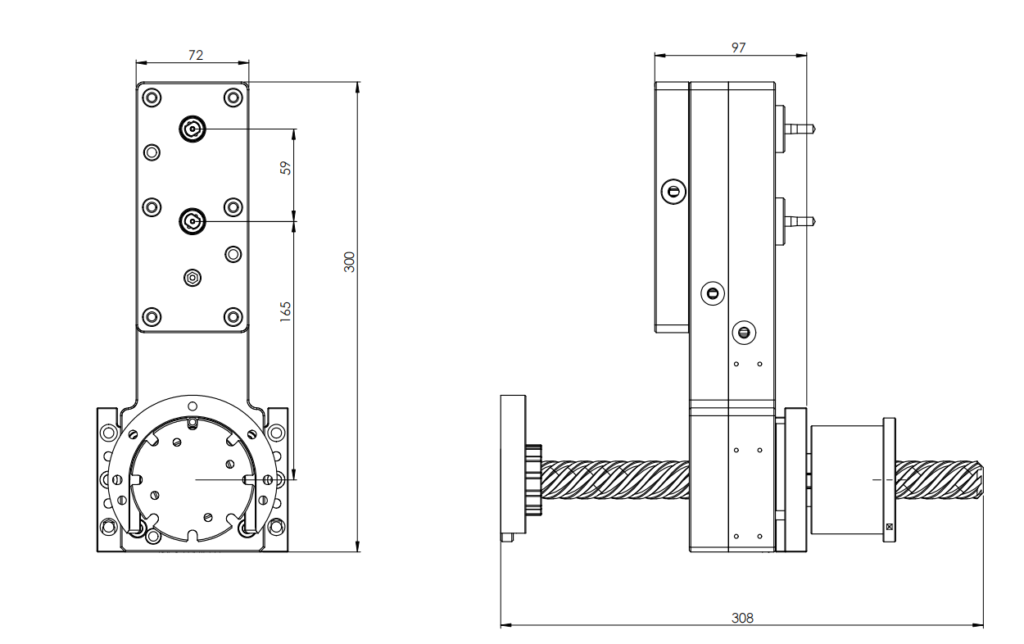

*3D Design Display

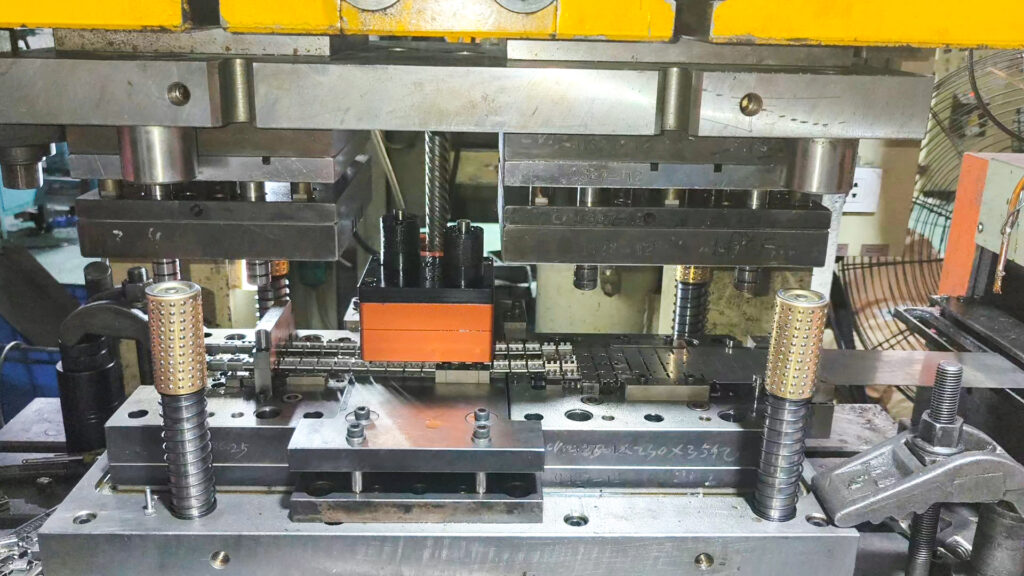

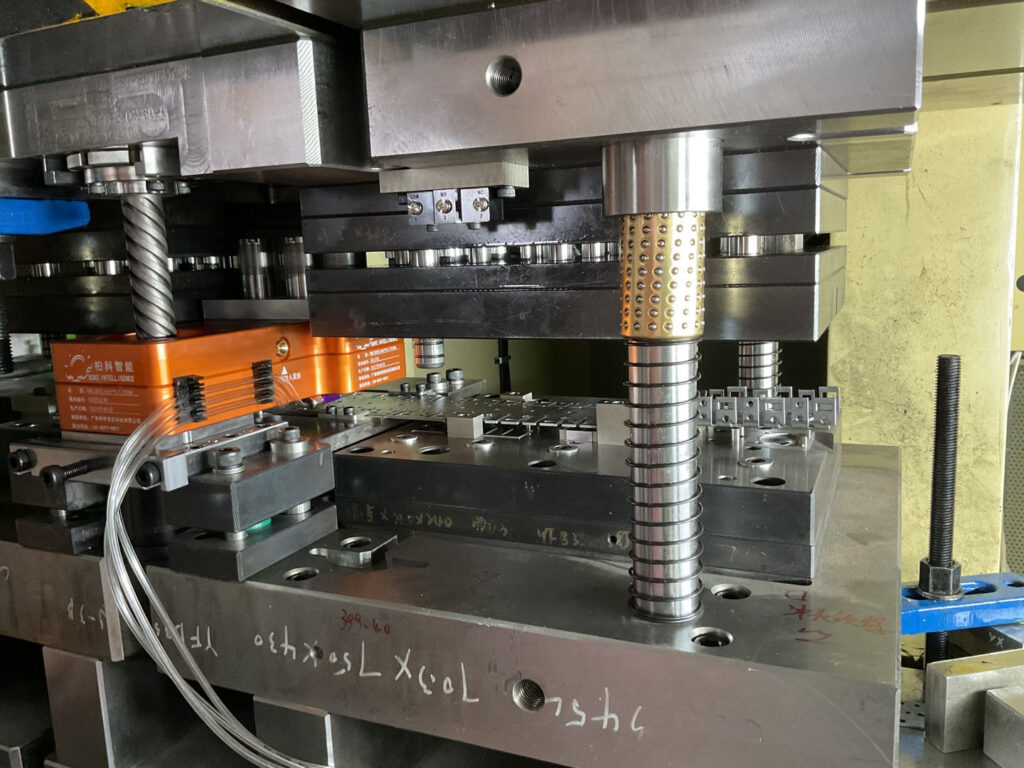

*After Installation

Printer Hardware Application

Technical Requirement

- 2 – M6*1.0, thread depth 3mm, material: SPCC.

- Press stroke: 120mm.

- Production requirement is more than 40 S.P.M

Recommended Machine

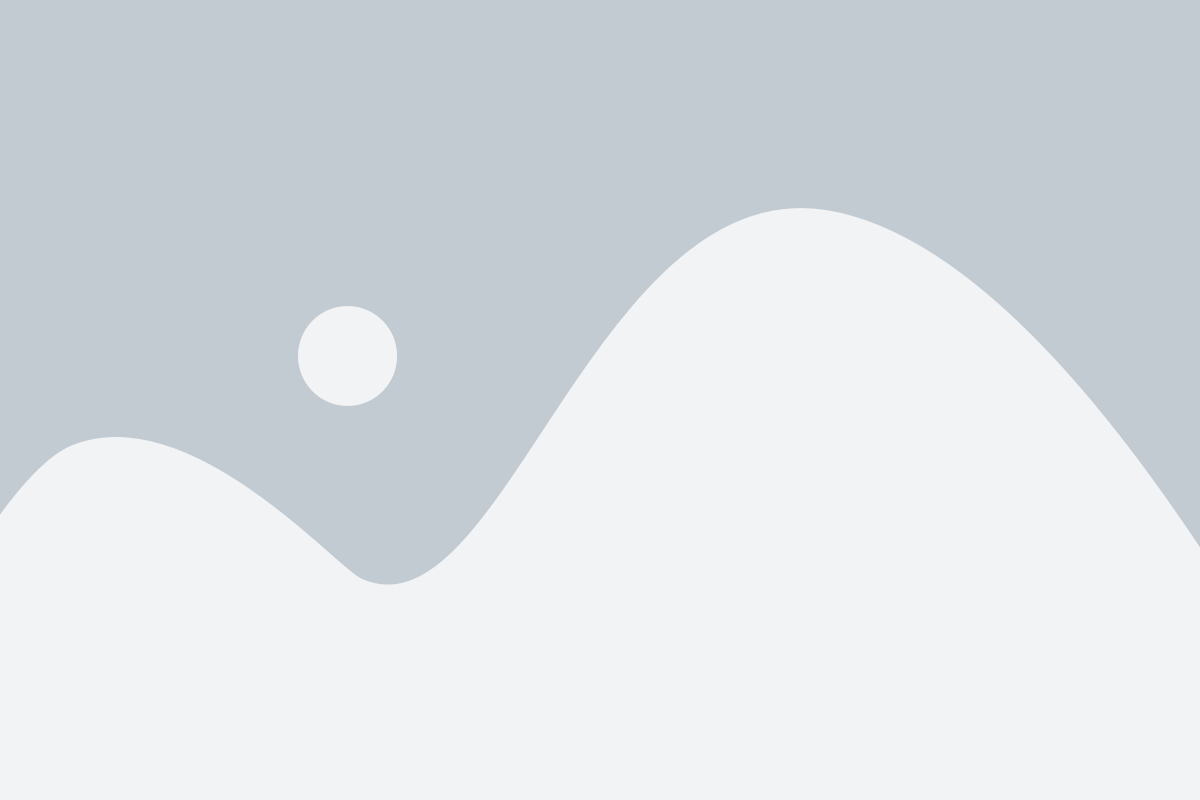

- Non-standard customization in-die tapping machine for BK-Z02-M6*1.0-T 120, that adopts quick-release structure.

Production Effect

- The design production stroke is 60 S.P.M. and the actual mass production speed is 45 S.P.M. Meets the production requirements.

- Quick-release model, easy and quick to replace taps.

- Pass the GO and NO GO Thread Plug Gauge.

Auto Parts Application

Technical Requirement

- 2 – M3*0.5, thread depth 3mm, material: galvanized sheet.

- Press stroke: no punch stroke limited.

- Production requirement is more than 40 S.P.M

Recommended Machine

- Non-standard customization in-die tapping machine without stroke limited for BK-IS-M3*0.5.

- Customized color.

Production Effect

- The design production stroke is 80 S.P.M. and the actual mass production speed is 40-50 S.P.M. Meets the production requirements.

- Quick-release model, easy and quick to replace taps.

- Pass the GO and NO GO Thread Plug Gauge.

BOKE In-mold Tapping Application Display

4 Videos

Compressor Accessories Application

Technical Requirement

- 2- M4*0.7, thread depth 2 mm, material: SPCC.

- Press stroke: 120mm.

- Production requirement is more than 20 S.P.M

Recommended Machine

- Non-standard customization in-die tapping machine for BK-Z04-M4*0.7-T 120, that adopts quick-release structure.

Technical Requirement

- 2 – M4*0.7, thread depth 2mm, material: SPCC.

- Press stroke: 120mm.

- Production requirement is more than 40 S.P.M

BOMETT In-mold Tapping Application Display

4 Videos

Curtain hardware

Demands

- Requires cutting taps.

- 2 – M5*0.8, thread depth 3mm, material: 201 stainless steel.

- Press stroke: 150mm.

- Production requirement: ≥60 S.P.M

Recommended Machine

- In order to use cutting taps, the structure of the mold needs to be improved. We adopted the design based on the BK-RN series in-mold tapping unit and made corresponding modifications to the structure.

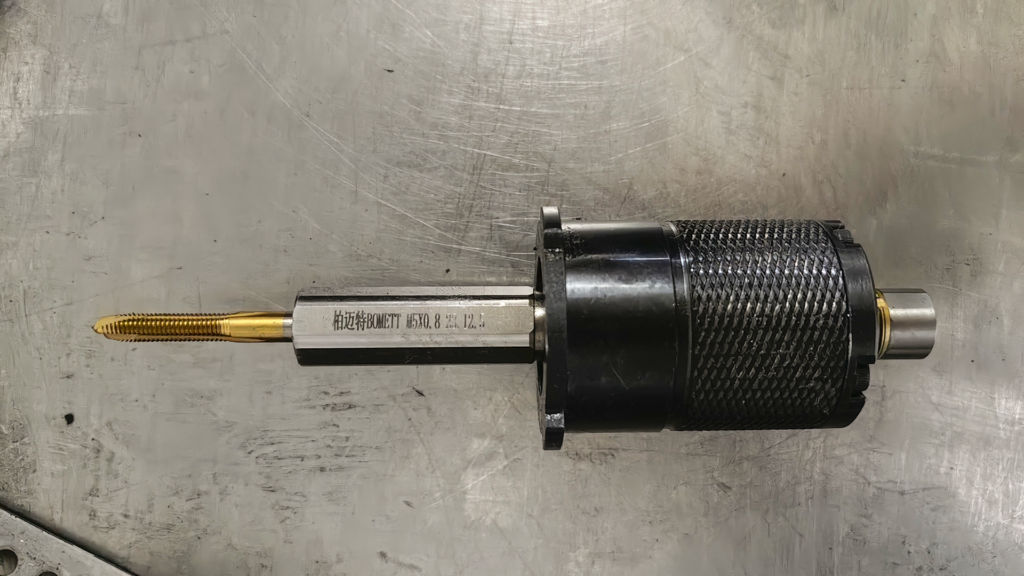

*Chuck for cutting taps

*Chuck for cutting taps