BOMETT In-mold Tapping Unit & Working Principle

BOMETT In-mold Tapping

In-mold tapping technology is a process for processing threaded holes on stamped parts in the metal stamping industry.

We have established our own BOMETT tapping system.

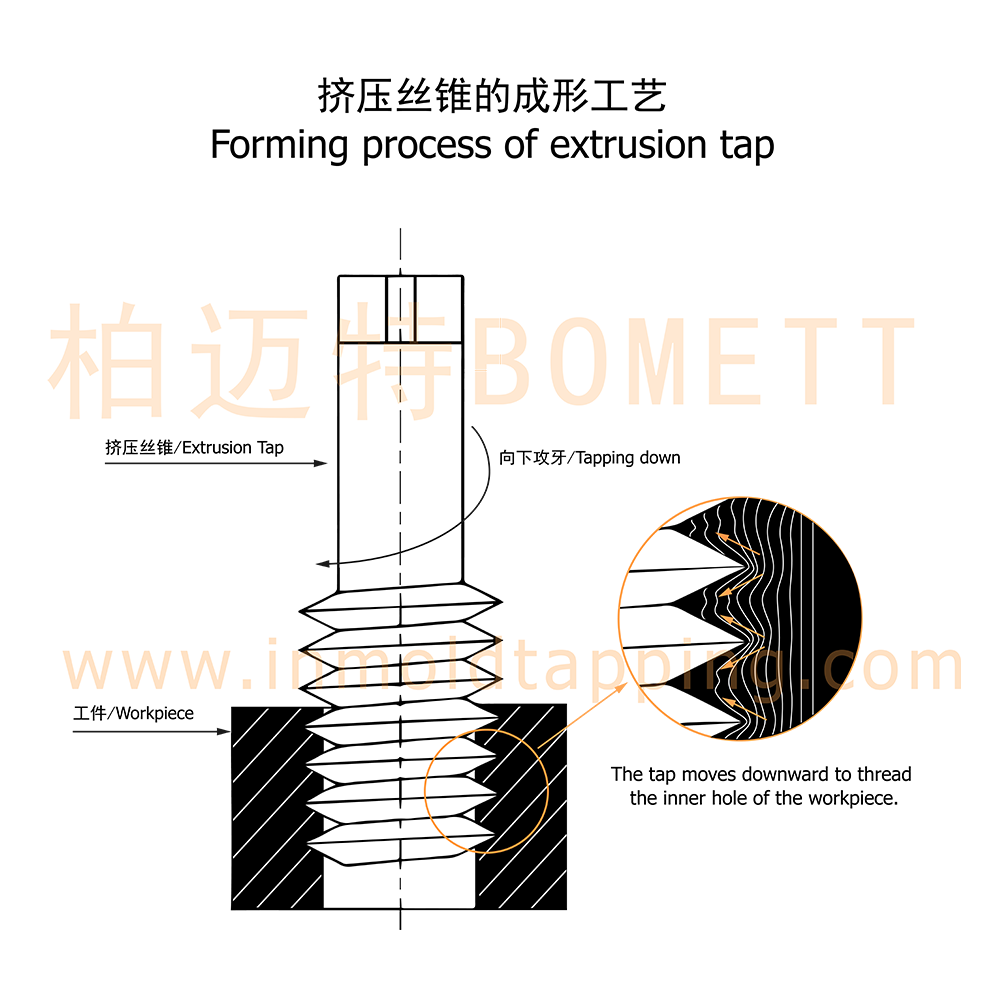

1.In-mold Tapping Machine Working Principle

In-mold tapping, or in-die tapping, is a technology that uses cold extrusion technology to form internal threads using the principle of metal plasticity.

During the stamping process, the extrusion tap moves along the inner hole of the workpiece, extruding threads on the surface, forming a thread with a uniform spiral groove of specified length and pitch.

2. Suitable Tapping Materials

Metal stamping materials with good plasticity are suitable for the in-mold tapping technology, such as low carbon steel, stainless steel, high strength steel, aluminum and aluminum plywood, cold rolled sheet, galvanized sheet, copper and copper alloy, etc.

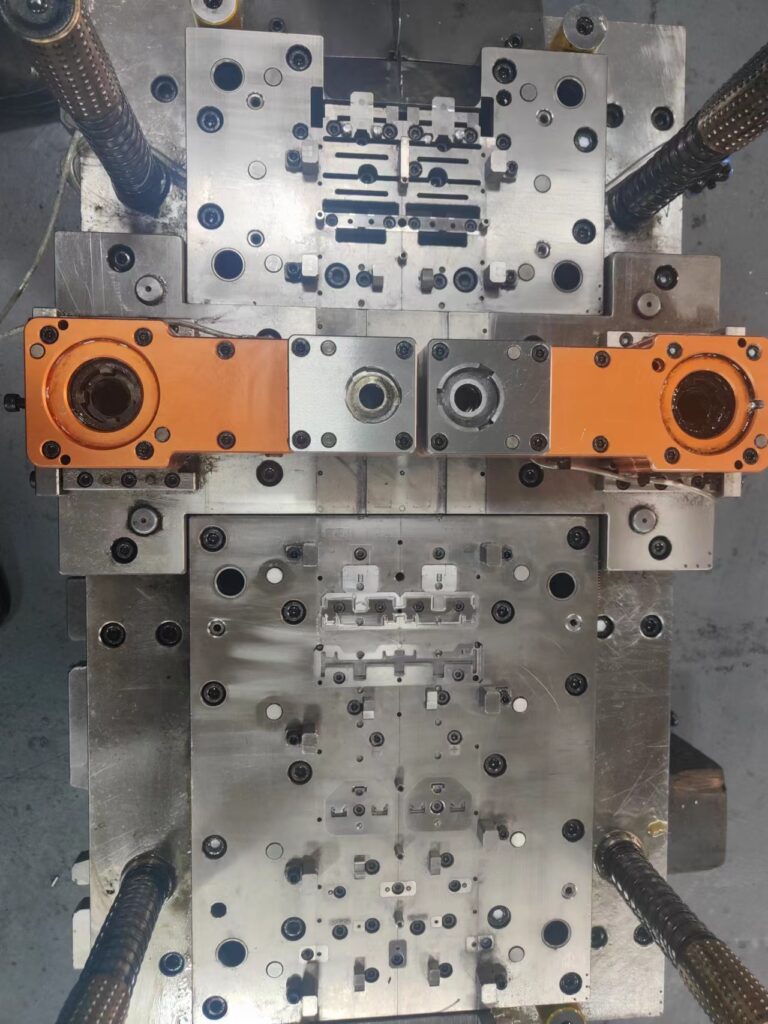

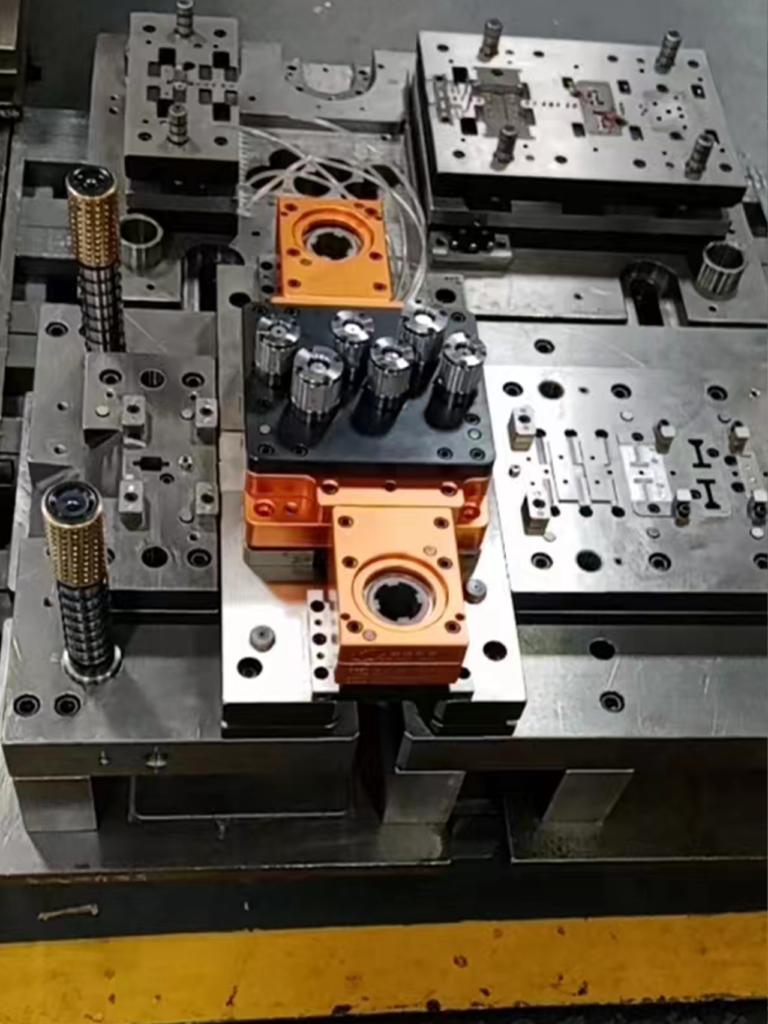

3.Applicable Molds

Suitable for metal progressive dies, continuous dies, precision dies, single punch dies, etc.

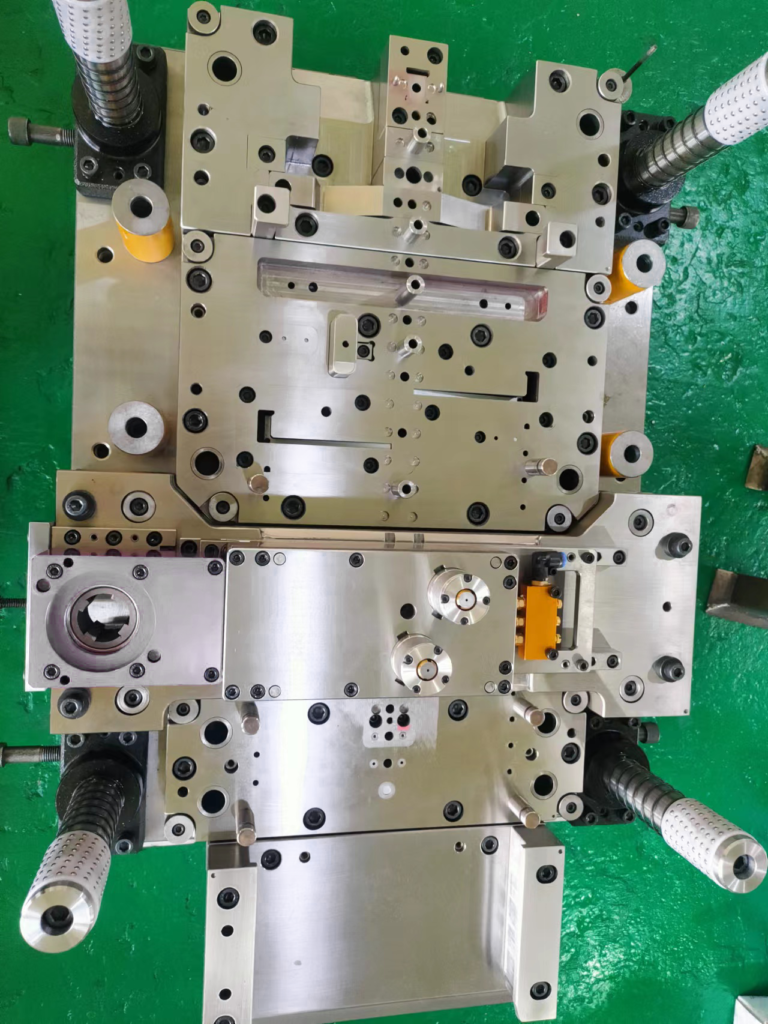

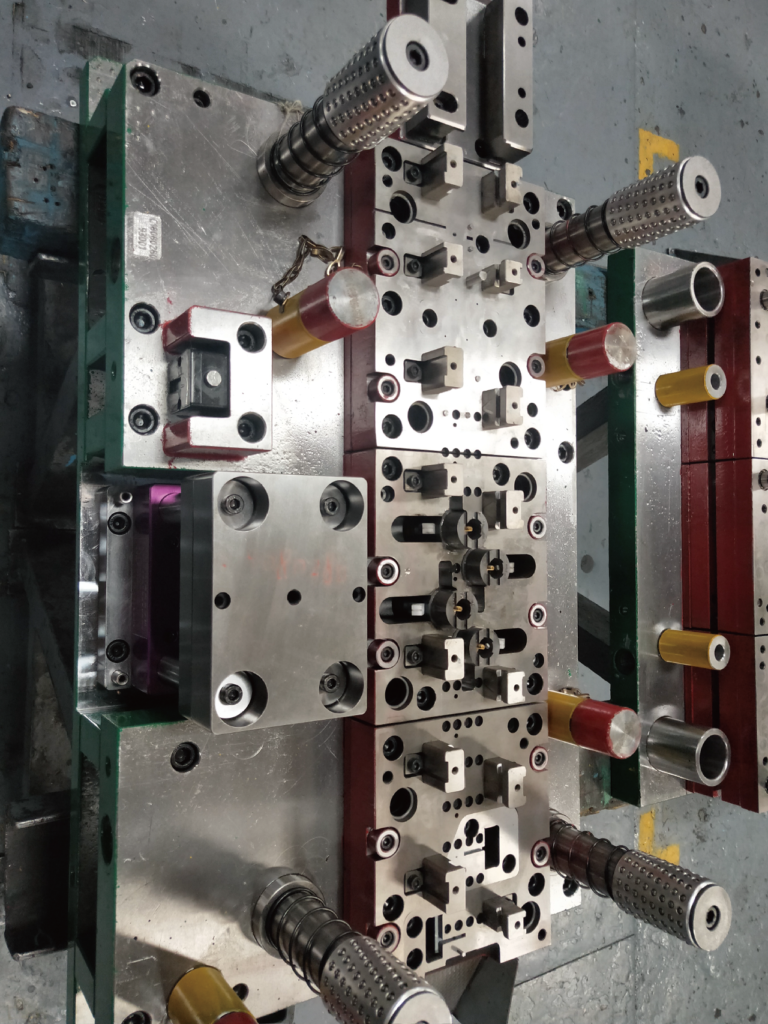

Progressive die with 2 sets of standard tapping machine (BK-R (MQ) )

Progressive die with tapping machine for 6 holes (BK-RN)

Progressive die with tapping machine for 2 holes (BK-ZON)

Progressive die with tapping machine for 6 holes without strock limited (BK-IS)

4. BOMETT Tapping Machine Category

According to different types of drives, BOMETT tapping machines are divided into mechanical tapping machine and servo tapping machine.

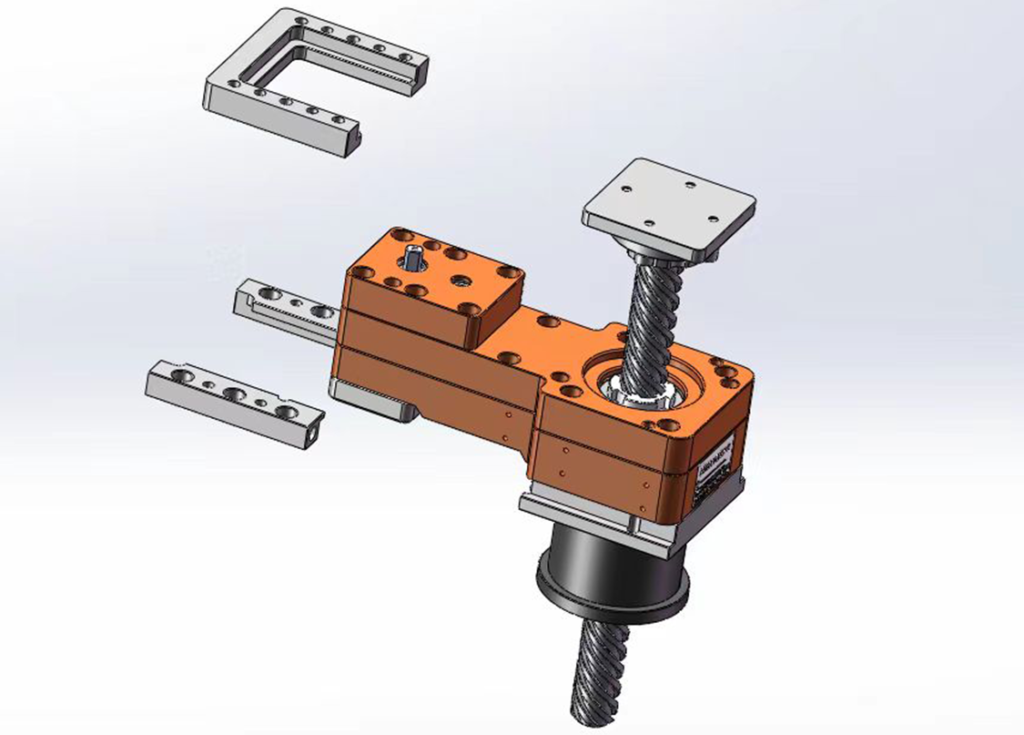

Mechanical tapping machine

BOMETT Mechanical in-mold tapping machine is a mechanical device installed in the die and driven by the punch up and down.

Multiple holes, and multiple specifications of thread patterns, can be mixed tapping.

Advantage:

- High efficiency, no manual labor required

- High product stability

- Low cost, low maintenance cost

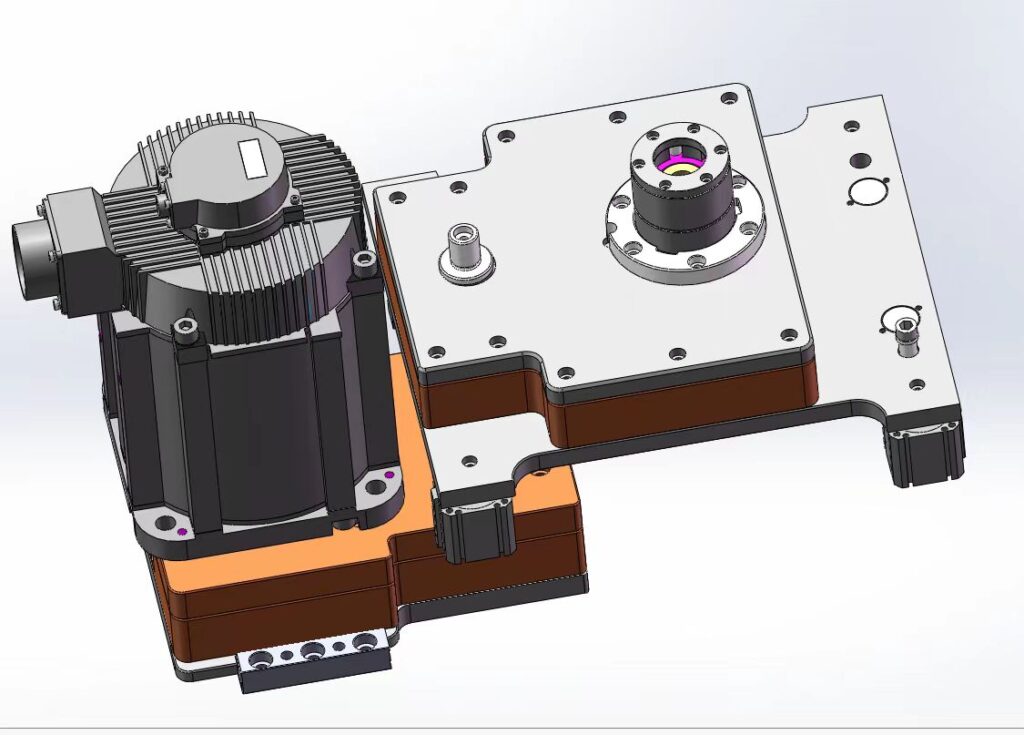

Servo tapping machine

BOMETT servo in-mold tapping machine, is an electric device driven by a servo motor.

Multiple holes, and multiple specifications of thread patterns, can be mixed tapping.

Advantage:

- Higher tapping efficiency for large threads

- No punch stroke limit

- No height restrictions on threaded holes

If you are interested in our BOMETT die tapping machines, welcome to consult. We can customize your product plan for you!