The difference between extrusion tap and cutting tap

Why choose extrusion taps for in-mold tapping?

This is affected by the in-mold processing technology. Let us conduct a detailed analysis.

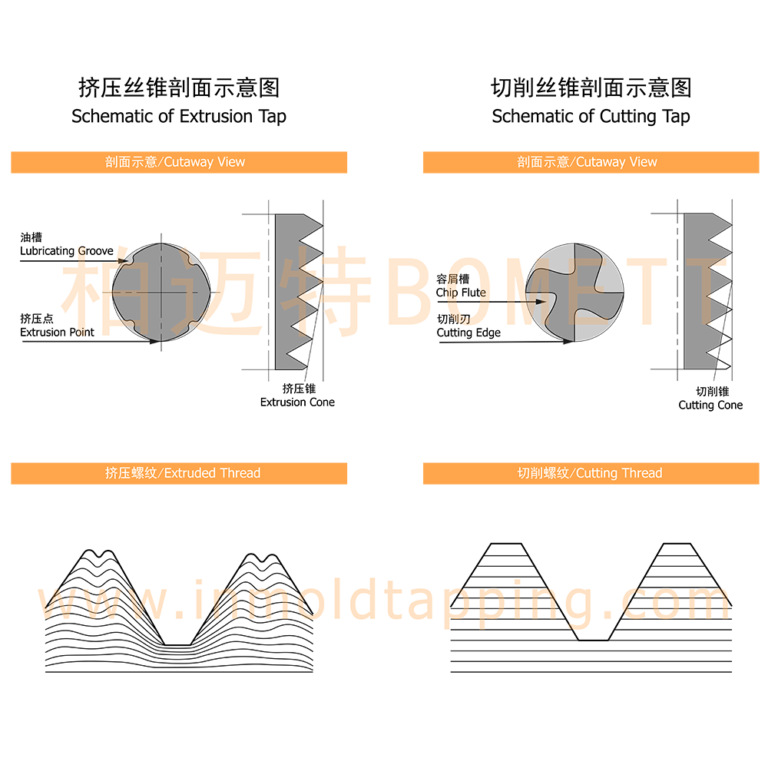

1. The extrusion tap

The extrusion tap is a special thread tool for cold extrusion processing of internal threads. No cutting groove, and no cutting chips when production.

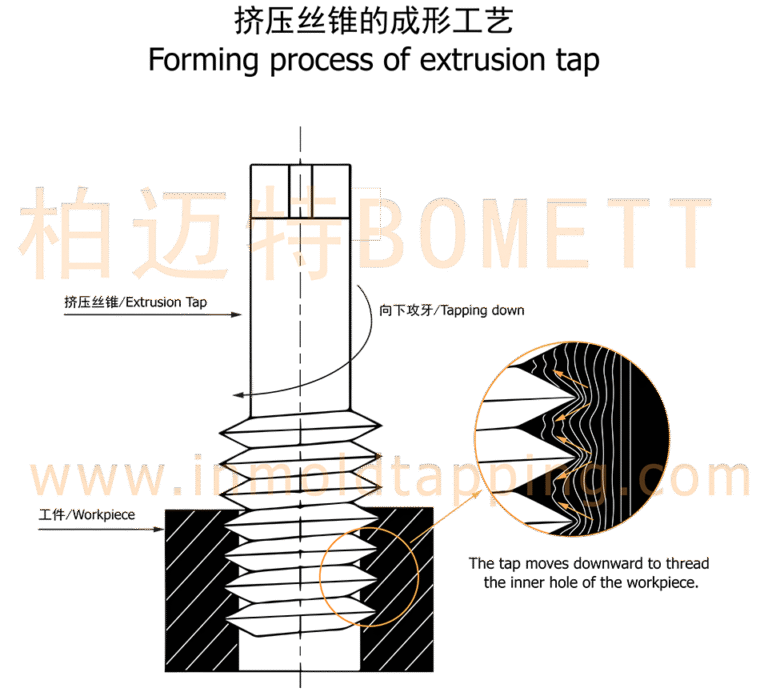

2. The working principle of extrusion tap

The extrusion tap uses an internal thread cold extrusion process based on the principle of metal plasticity. It is a technology that uses the thread profile on the edge of the extrusion tap to squeeze the metal in the bottom hole of the workpiece multiple times to cause plastic deformation of the metal to form internal threads.

3.The difference between extrusion tap and cutting tap

Extrusion taps and cutting taps are two different types of tools used to create internal threads. The main difference between them is the way they form their threads.

Cutting taps remove material from a workpiece to form threads. They have cutting edges and grooves, which generate chips during the cutting process.

Extruding a tap does not remove material from the workpiece. Instead, they work by cold forming threads through plastic deformation of the workpiece material. The surface of the extrusion tap is smooth and groove-free, so no chips are generated during the thread forming process.

4. The advantages of extrusion tap

- No cutting grooves, no cutting chips produced during processing.

Compared with traditional cutting taps, the thread processed by extrusion taps have the advantages of high strength and high wear resistance.

Compared to cutting taps, extrusion taps produce threads faster and last longer.

In-mold tapping is used in conjunction with continuous dies, and threads are processed synchronously during the stamping process. Extrusion taps process threads through a cold extrusion process and do not produce cutting chips. This ensures a clean working environment, and then, ensures product quality. Learn more about the technical parameters of commonly used extrusion taps.

To find out which tapping machine model is suitable for your product, you can browse bomett tapping devices.