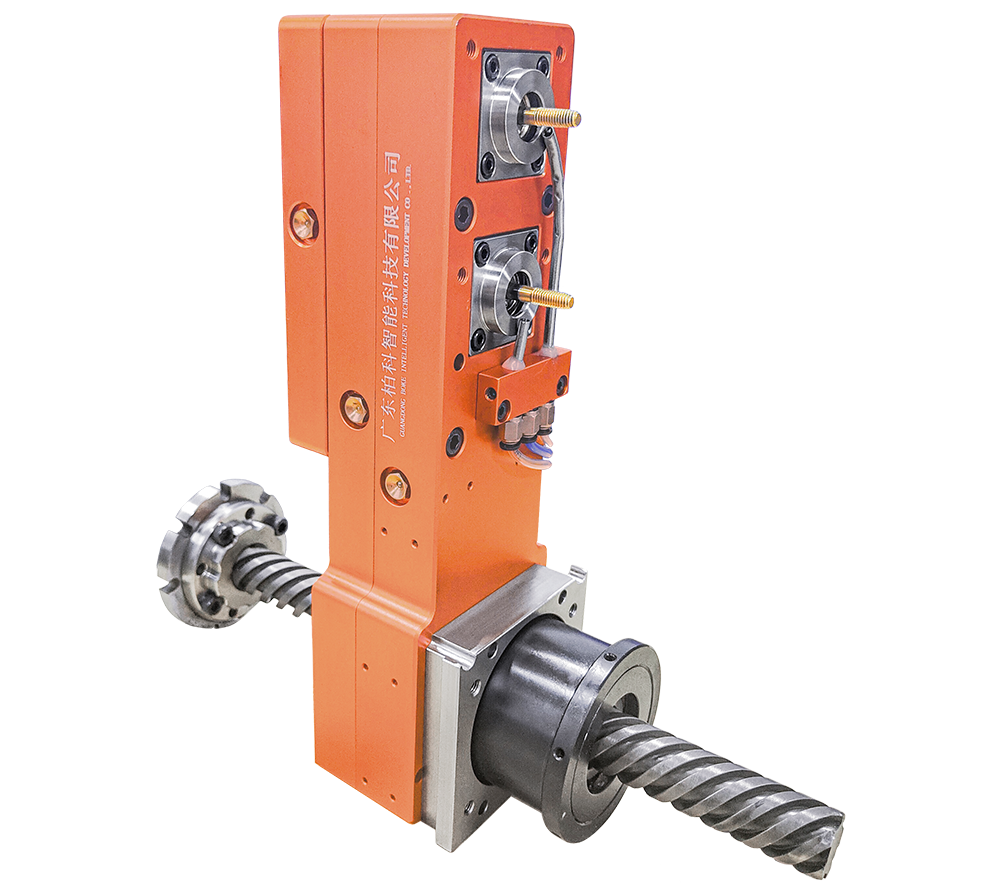

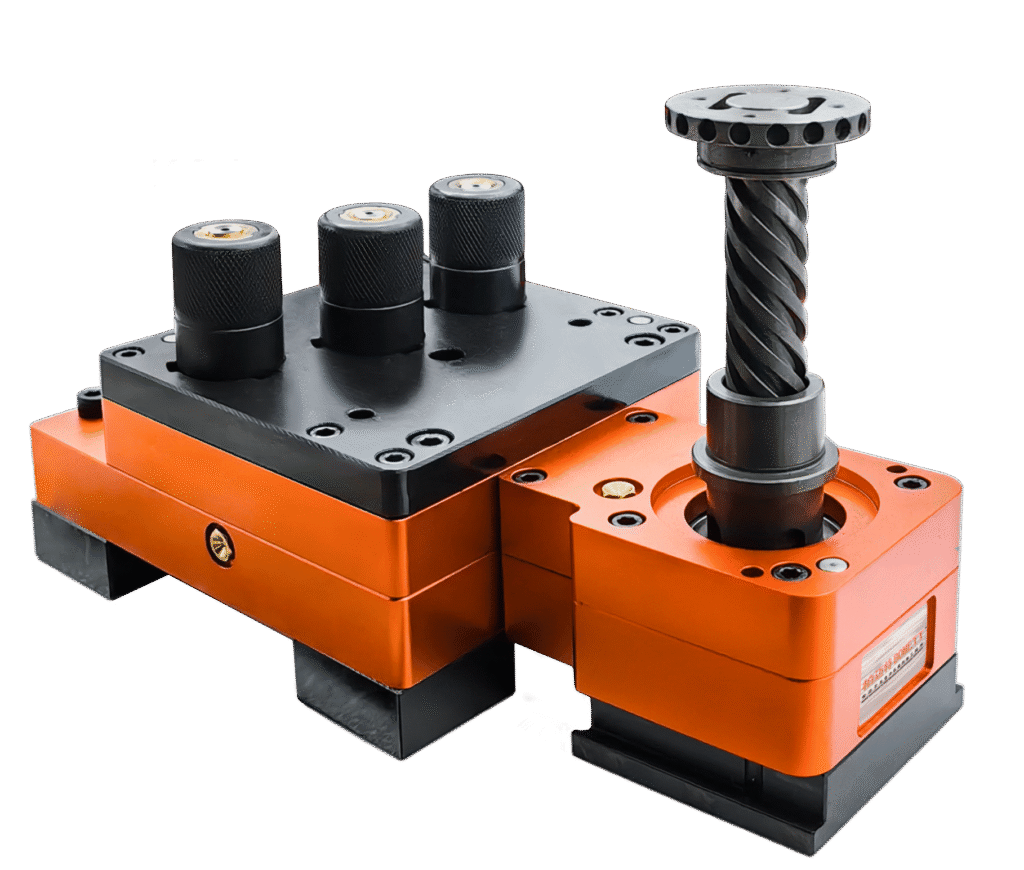

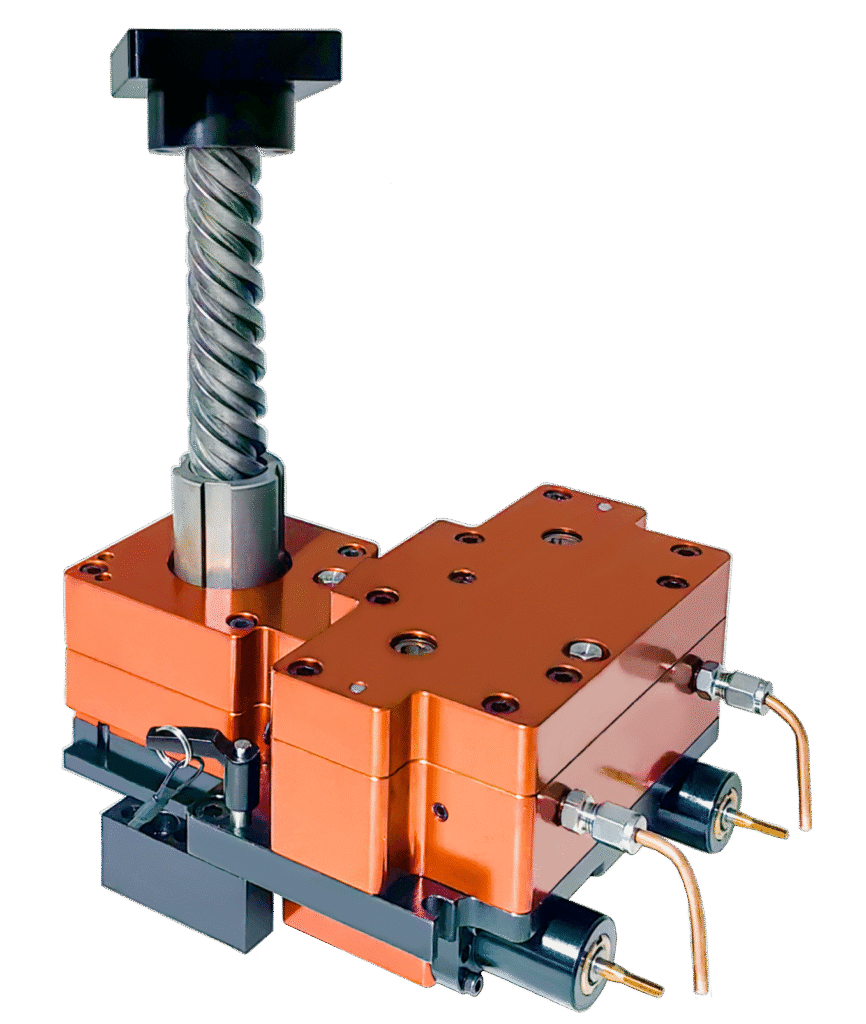

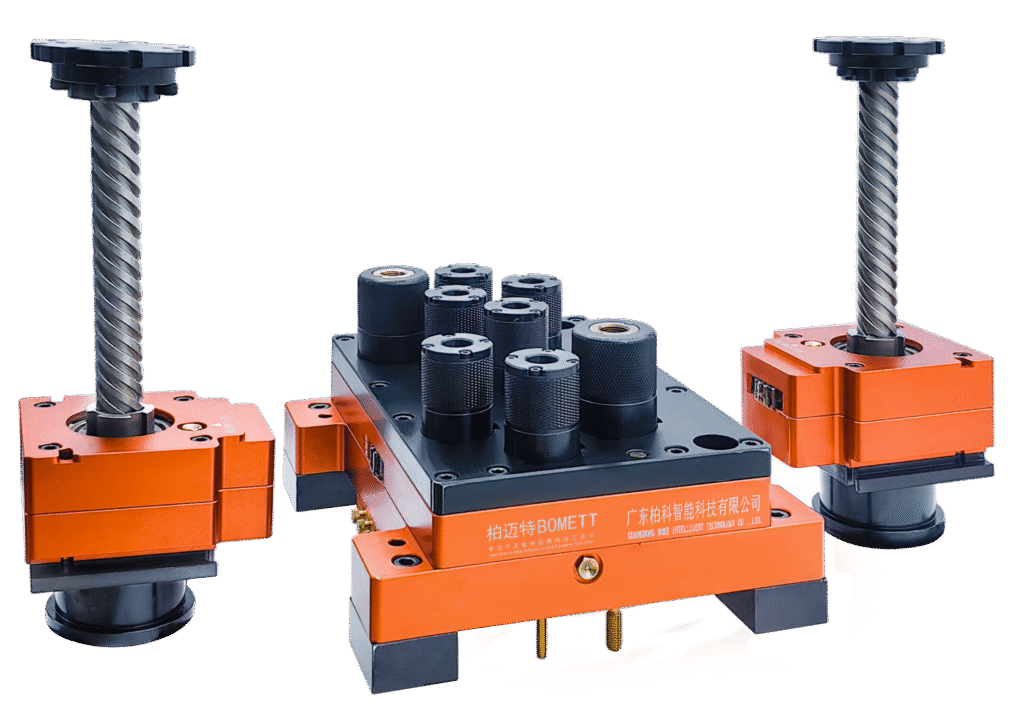

Multi-hole Series

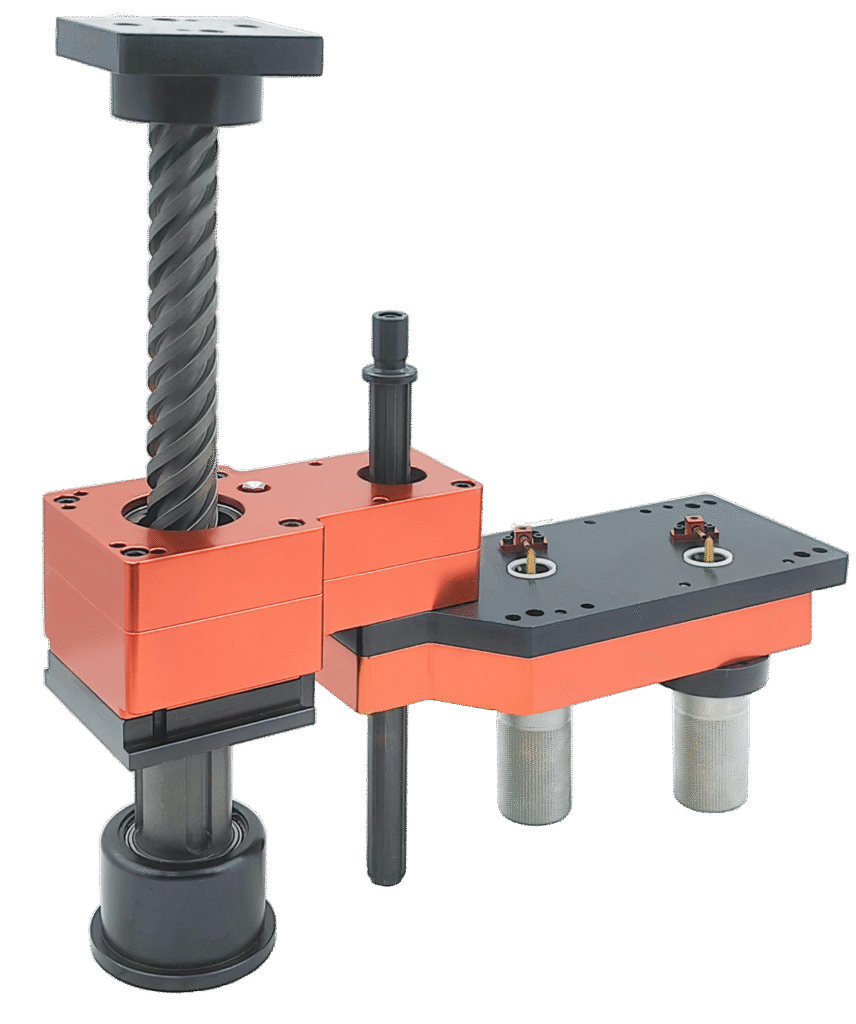

Multi-hole in-mold tapping is an innovative upgrade structure based on the single-hole tapping structure, which can adapt to more complex tapping needs.

The tapping of multiple parts can be completed synchronously in one operation,which greatly reduces the processing time.

Tapping units are non-standard customized devices. If you are looking for a suitable model, please contact the Bomett team.

We will provide professional advice in a timely manner.

Learn more about the applicable conditions of BOMETT models, and find the model that best suits your product.