Position Detection

The purpose of the detection device is to detect problems such as incomplete tapping and tapping position deviation, effectively ensuring product qualification while also protecting the mold and tapping unit.

Position detection, is mainly used to detect inadequate feeding.

Positioning detection can be designed on tapping machines or molds depending on different situations.

If you want to know more about the detection device information, please contact the Bomett team. We will provide professional advice in a timely manner.

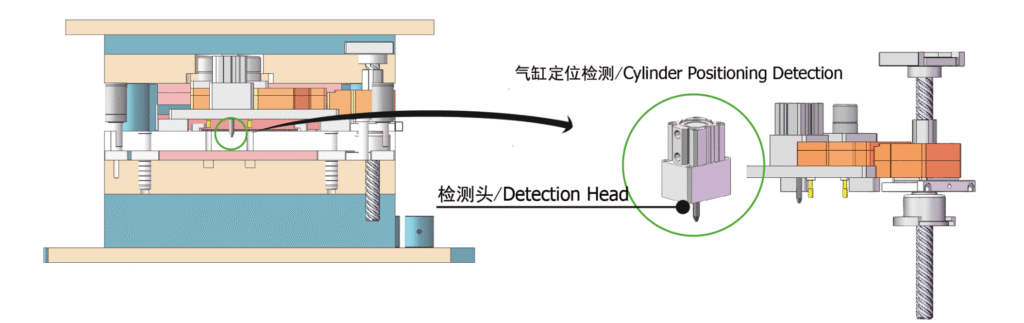

Cylinder Position Detection

Technical Features

- Positioning detection of tapped holes prior to tapping to prevent and detect belt feeding out of place.

- Cylinder positioning detection, no tapping hole limitations.

- Designed for stamping processing, it replaces manual monitoring and performs real-time detection.

- Can be designed for simple mechanical positional detection, or can be designed with an electrified control box.

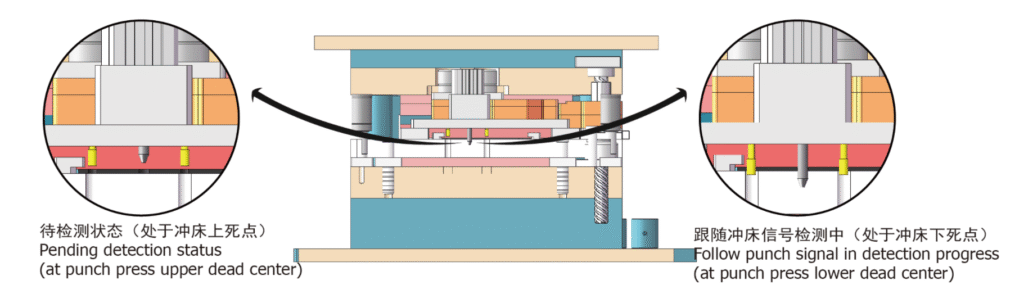

Testing Demonstration